MHE®301

Health Care

Health Care| Metal base type | Copper |

| Layers | 1 |

| Finished thickness (mm) | 3.38 |

| Copper foil (Oz) | 2 |

| Surface finish | ENIPIG |

| Solder mask color | Black |

| Legend color | White |

| Thermal conductivity (W/m.k) | 398 |

| Thermal resistance (°C/W) | 0.015 |

| Tg (°C) | 110 |

| MOT (°C) | 130 |

Health Care

Health Care| Metal base type | Copper |

| Layers | 1 |

| Finished thickness (mm) | 3.38 |

| Copper foil (Oz) | 2 |

| Surface finish | ENIPIG |

| Solder mask color | Black |

| Legend color | White |

| Thermal conductivity (W/m.k) | 398 |

| Thermal resistance (°C/W) | 0.015 |

| Tg (°C) | 110 |

| MOT (°C) | 130 |

Automotive electronics

Automotive electronics| Metal base type | Copper |

| Layers | 1 |

| Finished thickness (mm) | 1.5 |

| Copper foil (Oz) | 1 |

| Surface finish | ENIG |

| Solder mask color | Green |

| Legend color | White |

| Thermal conductivity (W/m.k) | 398 |

| Thermal resistance (°C/W) | 0.015 |

| Tg (°C) | 150 |

| MOT (°C) | 130 |

Electric power supply

Electric power supply| Metal base type | Copper-aluminum composite base |

| Layers | 1 |

| Finished thickness (mm) | 1.5 |

| Copper foil (Oz) | 2 |

| Surface finish | OSP |

| Solder mask color | White |

| Legend color | Black |

| Thermal conductivity (W/m.k) | 170 |

| Thermal resistance (°C/W) | |

| Tg (°C) | 150 |

| MOT (°C) | 130 |

Electric Torch

Electric Torch| Metal base type | Copper |

| Layers | 1 |

| Finished thickness (mm) | 1.0 |

| Copper foil (Oz) | 1 |

| Surface finish | ENIPIG |

| Solder mask color | White |

| Legend color | Black |

| Thermal conductivity (W/m.k) | 401 |

| Thermal resistance (°C/W) | 0.03 |

| Tg (°C) | 140 |

| MOT (°C) | 130 |

High Bay

High Bay| Metal base type | Copper |

| Layers | 1 |

| Finished thickness (mm) | 1.2 |

| Copper foil (Oz) | 1OZ |

| Surface finish | ENIPIG、ENIG |

| Solder mask color | White |

| Legend color | Black |

| Thermal conductivity (W/m.k) | 401 |

| Thermal resistance (°C/W) | 0.03 |

| Tg (°C) | 140 |

| MOT (°C) | 130 |

High Bay

High Bay| Metal base type | Copper |

| Layers | 1 |

| Finished thickness (mm) | 1.2 |

| Copper foil (Oz) | 1 |

| Surface finish | ENIPIG |

| Solder mask color | White |

| Legend color | Black |

| Thermal conductivity (W/m.k) | 401 |

| Thermal resistance (°C/W) | 0.03 |

| Tg (°C) | 140 |

| MOT (°C) | 130 |

High Bay

High Bay| Metal base type | Copper |

| Layers | 1 |

| Finished thickness (mm) | 1.2 |

| Copper foil (Oz) | 1 |

| Surface finish | ENIPIG |

| Solder mask color | White |

| Legend color | Black |

| Thermal conductivity (W/m.k) | 401 |

| Thermal resistance (°C/W) | 0.03 |

| Tg (°C) | 140 |

| MOT (°C) | 130 |

High Bay

High Bay| Metal base type | Copper |

| Layers | 1 |

| Finished thickness (mm) | 1.2 |

| Copperfoil(Oz) | 1 |

| Surface finish | ENIPIG |

| Solder mask color | White |

| Legend color | Black |

| Thermal conductivity (W/m.k) | 401 |

| Thermal resistance (°C/W) | 0.03 |

| Tg (°C) | 140 |

| MOT (°C) | 130 |

Laser Projector

Laser Projector| Metal base type | Copper |

| Layers | 2 |

| Finished thickness (mm) | 5.0 |

| Copper foil (Oz) | 2 |

| Surface finish | ENIG |

| Solder mask color | White |

| Legend color | |

| Thermal conductivity (W/m.k) | 401 |

| Thermal resistance (°C/W) | 0.028 |

| Tg (°C) | 150 |

| MOT (°C) | 130 |

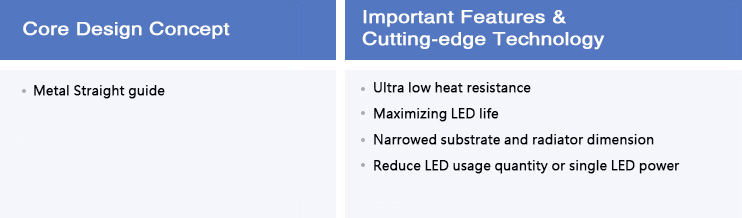

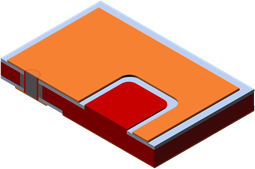

1. Does MHE®301 belongs to Metal Core PCB or not?

MHE301, a unique member of MCPCB family, which is designed based upon the concept of direct metal conduction, is produced by special PCB manufacturing process and technology advantages. Due to its technology cutting-edge, the heat can be dissipated more efficiently.

2. What is the conventional thermal conductivity of MHE®301?

MHE®301 possesses a thermal conductivity of 400W/m.K and its thermal resistance is 0.100~0.638k/W.

rbshareholder@gmail.com

rayben@rayben.com

sales@rayben.com

+86-756-6320666